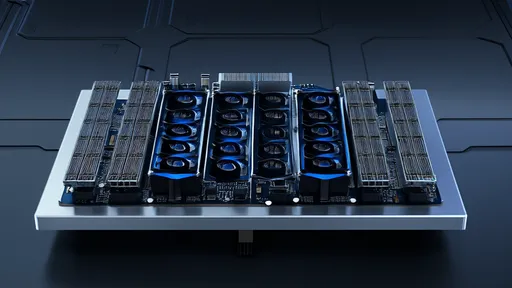

The rapid evolution of high-performance computing and data centers has brought thermal management to the forefront of technological challenges, particularly in the context of photonic-electronic co-packaging. As the demand for faster data transmission and lower latency grows, integrating optical interconnects with traditional electronic circuits becomes essential. However, this convergence introduces significant thermal complexities that require innovative solutions to maintain reliability and efficiency.

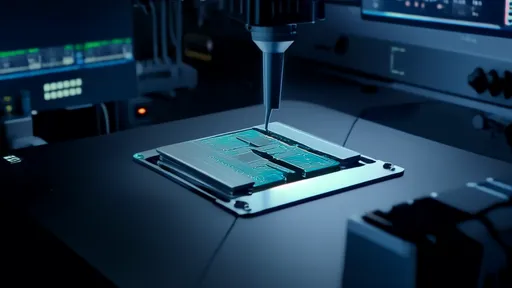

Photonic-electronic co-packaging merges optical and electronic components into a single module, reducing the distance between them and minimizing signal losses. While this integration enhances performance, it also generates concentrated heat in a compact space. Unlike conventional electronic systems, where heat dissipation follows well-understood pathways, co-packaged systems must account for the thermal interactions between lasers, modulators, and high-speed transistors. The challenge lies in managing these thermal loads without compromising the integrity of sensitive photonic components.

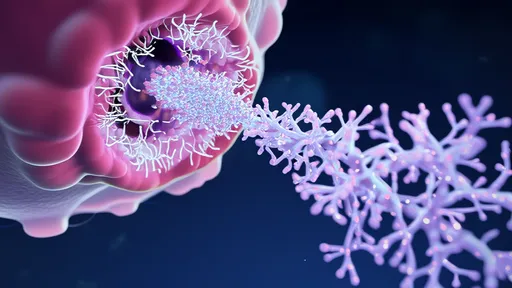

Thermal management in co-packaged systems is not just about cooling—it’s about precision. Photonic devices, such as silicon photonic chips, are highly sensitive to temperature fluctuations. Even minor deviations can alter their optical properties, leading to wavelength drift or increased signal noise. On the other hand, electronic components like processors and ASICs generate substantial heat, which, if not properly managed, can degrade neighboring photonic elements. This delicate balance necessitates advanced cooling strategies tailored to the unique requirements of hybrid systems.

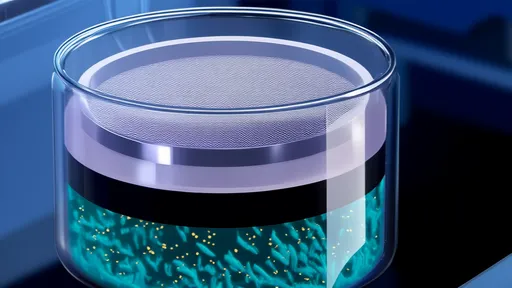

One promising approach involves microfluidic cooling channels embedded directly within the co-packaged module. These channels circulate coolants in close proximity to heat-generating components, extracting thermal energy efficiently. Unlike traditional heat sinks or air cooling, microfluidics offer localized cooling with minimal thermal resistance. Researchers have demonstrated that such systems can reduce junction temperatures by up to 30%, significantly improving the lifespan and performance of both photonic and electronic elements. However, integrating microfluidics introduces its own set of challenges, including fluidic-thermal-mechanical coupling and potential leakage risks.

Another critical consideration is material selection. The thermal conductivity of substrates and interposers plays a pivotal role in heat dissipation. Materials like silicon carbide and diamond are gaining traction due to their exceptional thermal properties, but their high cost and manufacturing complexity remain barriers. Meanwhile, advanced thermal interface materials (TIMs) are being developed to enhance heat transfer between dissimilar materials in co-packaged systems. These TIMs must not only exhibit high conductivity but also maintain stability under mechanical stress and thermal cycling.

The industry is also exploring passive cooling techniques, such as phase-change materials (PCMs), which absorb and release heat during state transitions. PCMs can be particularly effective in managing transient thermal spikes, a common occurrence in high-speed data transmission. By incorporating PCMs into the packaging architecture, designers can smooth out temperature variations and reduce the burden on active cooling systems. Nevertheless, optimizing the placement and composition of PCMs requires a deep understanding of the thermal dynamics within co-packaged modules.

Beyond hardware solutions, intelligent thermal management through software is emerging as a key enabler. Machine learning algorithms can predict thermal behavior based on workload patterns, dynamically adjusting cooling mechanisms to preempt overheating. For instance, by analyzing historical data, these algorithms can anticipate periods of high computational demand and proactively increase coolant flow or modulate laser power. This proactive approach not only enhances reliability but also improves energy efficiency, a critical factor for large-scale deployments in data centers.

The future of photonic-electronic co-packaging hinges on overcoming these thermal challenges. As the industry moves toward tighter integration and higher densities, interdisciplinary collaboration will be essential. Material scientists, photonic engineers, and thermal experts must work together to develop holistic solutions that address both performance and reliability. The stakes are high—failure to manage heat effectively could stifle the adoption of co-packaging, limiting the potential of next-generation computing and communication systems.

In summary, thermal management in photonic-electronic co-packaging is a multifaceted problem demanding innovation across multiple domains. From advanced cooling techniques to smart material choices and AI-driven optimization, the path forward requires a concerted effort. As research progresses, the solutions developed today will pave the way for faster, more efficient, and thermally sustainable systems tomorrow.

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025